HDD ACCESSOIRES RENTAL |

Pump units P7D & P10D

Unit description:

Unit description: The P7D and P10D are specially developed for the HDD drilling rigs in the range to abt. 80 ton. The pump capacity for the P7D is up to 700 ltr/min and for the P10D to 1000 ltr/min. The P7D is one 8 ft module, the P10D includes two modules that are easy connected by spicer coupling.

Driver:

Installed in the P7D is a 75 kW engine, in the P10D we have installed a 170 kW engine with 3 speed gearbox.

Drive system:

The P7D pump is driven by gearbox and chain belt, in the P10D a 3 speed gearbox and a chain reduction is installed.

Pump:

The pump in the P7D is a 3 1/2” stroke triplex piston pump with 3 ½” alternative 4” liners, the P10D is a 5” stroke triplex piston pump with 4” liners.

P10D is with forced lubrication system. Both pumps have liner wash system. Hydrostatic test pressure fluid end 100 bar.

| Capacity: | Liner | Pressure Bar | Q pump min. | ltr/min max. |

| P7D | 3,5" | 70 | 200 | 510 |

| 4" | 50 | 260 | 670 | |

| P10D | 4" | 70 | 150 | 1000 |

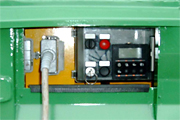

Remote Panel  |

Hammer union fig 200 |

Remote unit for the pump speed, on/off,

basic engine information.

| Unit connections: | Mud inlet | Mud outlet | Safety valve |

| P7D | 3" | 2" | 2" |

| P10D | 4" | 2" | 2" |

It is necessary to charge the suction line to the pump.

| Unit size & weight: | P7D | 8 ft ISO std. container | |

| Dry weight: 3000 kg | |||

| P10D | pump module | 2,2 x 2 x 1,6 mtr | |

| Dry weight 3000 kg | |||

| engine module | 8 ft container - 2,5 mtr height | ||

| Dry weight: 3000 kg |

| Fuel tank: | P7D | 200 ltr |

| P10D | 350 ltr |

Marindco Deutschland GmbH Wrister Strasse 24 24576 Weddelbrook Tel. +49 (0)4192 897 100 Fax +49 (0)4192 897 153 E-Mail info@marindco.de